Kwiaty cięte, choć przepiękne, mają jedną wadę – ich świeżość trwa stosunkowo krótko. Ale czy wiesz, że istnieje sposób, aby cieszyć się ich urodą znacznie dłużej? Kluczem jest zastosowanie odpowiedniej odżywki dla ciętych kwiatów, któraCzytaj więcej

Odżywki do ciętych kwiatów – sekret długowieczności twoich bukietów

Każdy, kto kiedykolwiek otrzymał bukiet kwiatów, zna ten uczucie – radość i zachwyt z powodu piękna, które jednak zbyt szybko przemija. Odżywki do ciętych kwiatów są kluczem do przedłużenia życia tych delikatnych dzieł natury, zapewniającCzytaj więcej

Drucik florystyczny – sekret mistrzowskich kompozycji kwiatowych

Drucik florystyczny, często niepozorny i ukryty wśród liści i płatków, jest jednym z najważniejszych narzędzi w arsenale każdego florysty. To dzięki niemu bukiety zachowują swój kształt, a kompozycje kwiatowe stają się dziełami sztuki. W tymCzytaj więcej

Drucik do kwiatów: mały element, wielkie możliwości

W świecie florystyki, gdzie każdy detal ma znaczenie, drucik florystyczny wyłania się jako nieoceniony, choć często niedoceniany, bohater. Ten skromny element jest kluczem do stworzenia wyjątkowych i trwałych kompozycji kwiatowych. Dziś przyglądamy się bliżej temu,Czytaj więcej

Taśma florystyczna – magiczne wiązanie kwiatowego świata

Taśma florystyczna to nie tylko narzędzie w rękach florysty – to małe cudo, które łączy naturę z kreatywnością, nadając każdej kompozycji kwiatowej niezwykły wyraz i trwałość.

Kreatywna florystyka: w świetle hurtowni florystycznej

W dzisiejszym świecie, gdzie sztuka florystyki staje się jednym z najbardziej inspirujących obszarów dekoracji, hurtownie florystyczne stanowią serce dla miłośników kwiatów, oferując nie tylko produkty, ale także kreatywną przestrzeń do realizacji marzeń.

Hurtownia florystyczna: oaza kwiatowej kreatywności

Hurtownie florystyczne to miejsca, w których kreatywność kwitnie w otoczeniu pięknych kwiatów i bogatego asortymentu akcesoriów florystycznych. Stanowią one fundament dla wielu profesjonalistów oraz miłośników sztuki tworzenia kompozycji kwiatowych. Wprowadźmy się w świat hurtowni florystycznychCzytaj więcej

Hurtownia florystyczna agatplus.com.pl: twoje kwiatowe źródło inspiracji

AgatPlus.com.pl to nie tylko kolejna hurtownia florystyczna, to miejsce, gdzie pasja do kwiatów łączy się z profesjonalizmem i szerokim asortymentem akcesoriów florystycznych. W tym artykule zapoznamy się bliżej z AgatPlus.com.pl i dowiemy się, dlaczego wartoCzytaj więcej

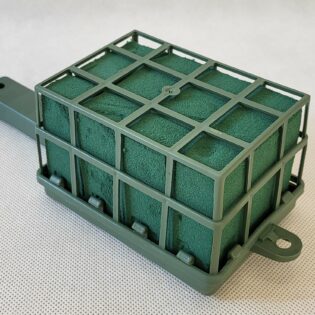

Akcesoria florystyczne: tworzenie zaczarowanych ogrodów

Sztuka florystyczna to magiczne połączenie natury, kreatywności i estetyki. Kwiaty i rośliny od wieków inspirują ludzi do tworzenia pięknych kompozycji, które wyrażają emocje i dodają uroku różnym wydarzeniom. Kluczową rolę w tym procesie odgrywają akcesoriaCzytaj więcej

Hurtownia florystyczna Agatplus: Twoje Centrum Kreatywnych Rozwiązań Kwiatowych

Hurtownia florystyczna Agatplus to miejsce, w którym pasjonaci florystyki, kwiaciarze, dekoratorzy i wszyscy związani z branżą kwiatową znajdą wszystko, czego potrzebują, by tworzyć piękne i wyjątkowe kompozycje kwiatowe. Od początku naszej działalności stawiamy na wysokąCzytaj więcej